Evatec is inside 80% of mobile devices in the market

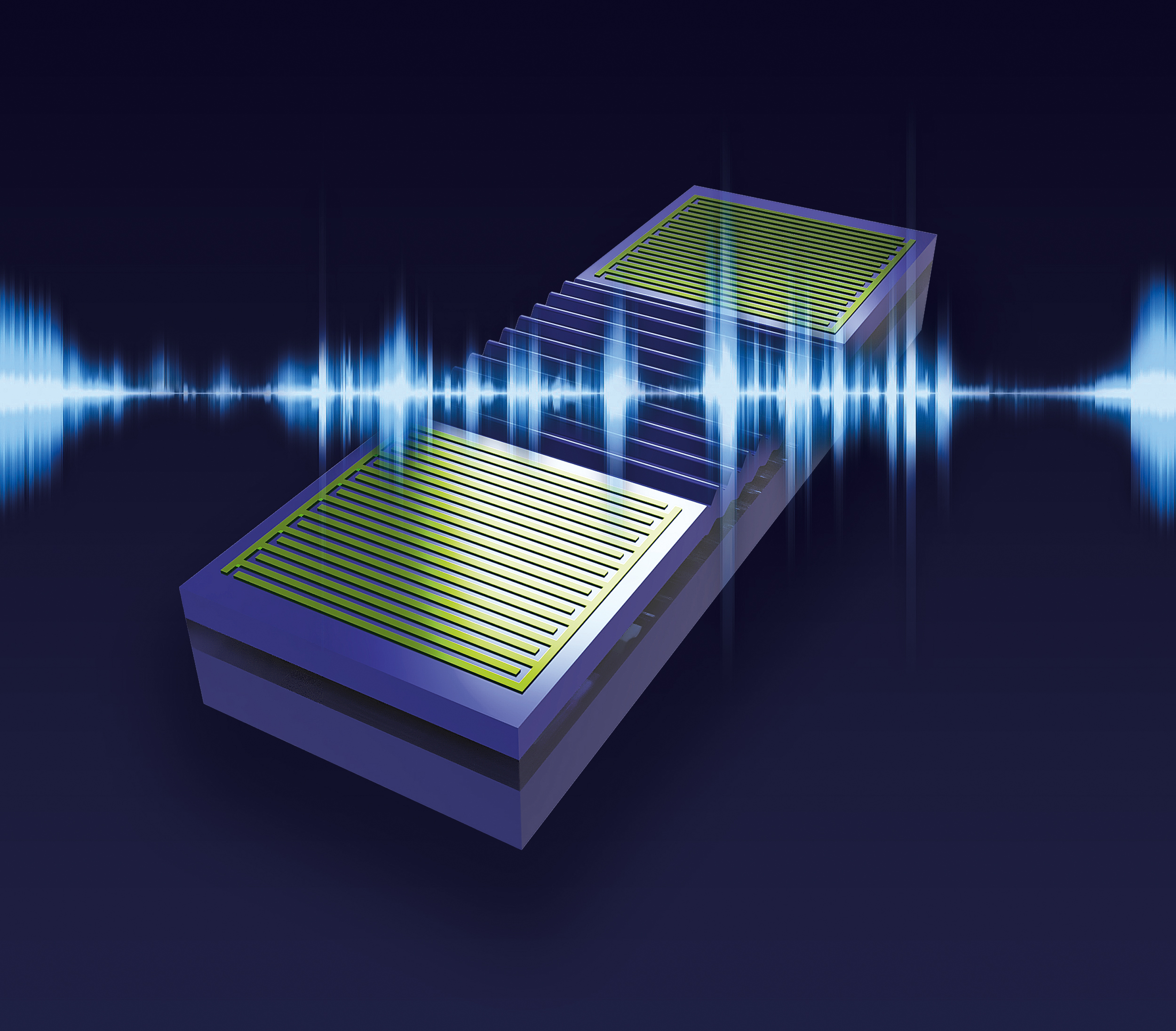

Thin film solutions for BAW filters

- Proven performance – 150 modules in 24/7 operation around the world

- Seed layers, AlScN and metal electrode processes

Thin film SAW technology

- Sputter of accoustic dielectrics (e.g SiO2, AlN or Ta2O5)

- Evaporation and sputtering for IDT Electrodes

RF-Power

- Conformal coatings on trenches up to 5:1 AR

- Epitaxial AlN and GaN sputtering

Driving down Cost of Ownership

- Secure "Cassette to Casette" processing

- Raising throughput in evaporation and sputter

Discover the Evatec advantage in Wireless

From high-performance RF filters ranging from lower frequencies towards 6G wireless devices, Evatec's evaporation and sputter platforms support a range of thin film processes for wireless communication applications. We cater for the gap filling and planarization processes used in temperature compensation of SAW devices. Our evaporation process specialists can advise the best production solutions for "lift off" for IDTs, metallization in HBT and p-HEMT manufacturing. Evatec experts in piezoelectrics can help you configure sputter deposition solutions for high-performance layers such as Al(1-x)ScxN (x > 36 at.%) for RF filter technology.

We ensure best-in-class thickness and stress uniformities for high production yields on wafer sizes up to 200mm.

SAW and BAW

Our thin film processes using evaporation or sputter support the manufacture of low-loss RF filters for wireless communication applications. Our BAKs can be custom configured as split chamber extended throw systems for "lift off" with manual, semi automated or fully-automated loading handling, whilst dedicated cathode technology on our CLUSTERLINE® 200 platform eliminates manual handling through cassette to cassette operation and enables the deposition of piezoelectric materials such as AlN and AlScN with the highest degree of crystal orientation and controlled stress non-uniformity for resonators, reflectors and electrodes. Our state-of-the epitaxial seed layer solution bring the electrode as well as piezoelectric layers performance to the next level by dramatically improving aspects such as crystal structure, roughness and conductivity.

Metallization Processes

Evatec's evaporation platforms, optimized for mass production with high-quality process performance, deliver reduced precious metals consumption using proprietary software like Unicalc. Systems with extended throw are ideal for "lift off" process geometries, ensuring zero side wall coverage for subsequent film patterning steps. From manual to semi-automatized and finally to fully-automatized wafer handling reducing the scrap yield to zero for precious wafers such as GaAs, LiNbO3 and LiTaO3, we offer a range of evaporation solutions from maximum flexibility to the highest throughput, lowest cost of ownership with highest energy efficiency. Why not take a look at our Multi BAK cassette to cassette solutions to see what's possible.

Configuration options for CLUSTERLINE® 200 include classical single substrate or batch processing for simultaneous handling of different substrate sizes and recipes maximizing tool utilization.

Production Tools

The Evatec Tool Portfolio for Wireless

Choose from Evatec's platforms based on your substrate, process requirements, throughput, and factory integration needs.

Our experts are available to assist you in finding the right platform tailored to your specifications. Alternatively, click on the button to explore each platform in detail.

BAK Family

Production-proven family of evaporators offering standalone chambers to fully automated multi-chambers including loadlocks equipped with overhead transport systems. Choose from standard or extended throw options for lift off processes up to 8 inches, enhancing throughputs while reducing precious metals consumption and reducing the scrap costs by avoiding manual handling.

CLUSTERLINE 200®

From single substrate processing for electrodes and piezoelectric deposition to dynamic batch processing for gap filling and planarization processes on wafer sizes up to 8-inch.

Read more about Wireless in our LAYERS magazine

BAW technology

Evatec shows how the latest thin film processes for deposition of both piezoelectric layers and eletrodes are helping customers keep leading performance in BAW filter technology.

Multi BAK

Three years ago, Evatec launched the Multi BAK, enhancing process repeatability and throughput with up to 4 BAK chambers. Recent developments offer more production choices for wireless, power, and optoelectronics applications.

BAK 941 - Making the great even better

In 2017, we introduced the BAK 1401, handling 24 wafers per batch. The BAK 1401 SC (split chamber) systems offer 10-20% higher throughputs and improved process repeatability. Learn how we're making these systems even better.