The BAK – Pushing boundaries in evaporation technology

Power Devices

- Backside Metallization with best materials utilization

- Precision and repeatability in “lift off”

Wireless

- Advanced solutions - IDT electrodes for TF-SAW

- Automated handling solutions for best CoO

Precision Optics

- From UV to IR - Delivering new levels of process control

- BB and hybrid Optical monitoring direct up to ????nm

MEMS

- Outstanding platform flexibility for deposition of metals, dielectrics, TCOs

- Co-evaporation processes - from quantum computing to digital scintillators

BAK Evaporators

With new levels of flexibility, and new levels of process control the BAK Evaporator is the industry leader in selected applications across Power Device, Wireless, LED, MEMS and Photonics applications. There is a BAK thats suitable for everyone - from the compact BAK 501 for universities and research institutions to the BAK 1401, a production giant.

Find out about the range of different configurations by clicking on the boxes below or contact us for immediate help.

Get Started

From R&D to mass production – find the right size and configuration for you.

Choose a Configuration

Choose a configuration to meet your requirements.

Sources & Tooling

50 years production know-how in Source & Tooling Solutions.

Custom Solutions

Custom sources, custom monitoring and custom engineering just for you.

Get Started - Find the right BAK for you

Step 1

Check what system capacity you need

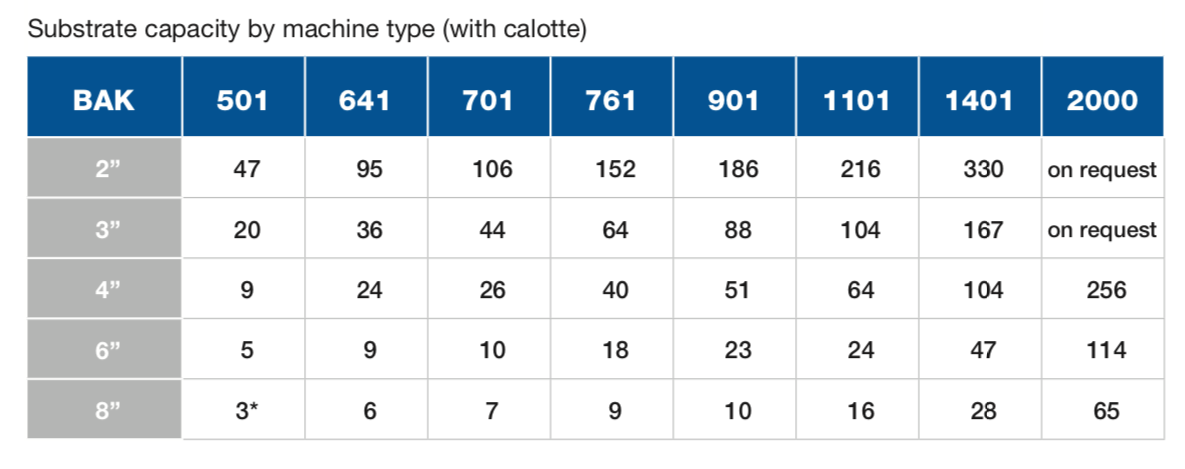

Start by selecting a basic platform size according to your substrate size and preferred batch capacity for standard calotte handling. View the capacity chart for different system sizes on the right side.

Step 2

Choose your sources, accessories and process control technologies

Take a quick look at our portfolio of sources and process accessories on the right - from effusion cells and digital beam sweep electron beam guns, to chamber heating and plasma sources for PIAD.

To read more about Evatec advanced process control technologies including quartz and optical monitoring click here

Step 3

Customize your BAK according to your processes and fab integration requirements

Investigate further custom options to build a BAK that’s just right for you.

- "Lift Off" platforms with extended throw for zero side wall coverage

- "Split Chamber" platforms for sensitive source materials and reduced batch cycle times

- Automated Handling options including single wafer transfer, assisted calotte load or full robot load or the calotte and transfer to the coating chamber from frontend cassettes

- Coating at an angle or rotating completely during the process

Step 4

Benefit from Evatec's Unicalc Solutions

Whatever configuration you choose, all our BAK family members come with 50 years of process know-how. Evatec Unicalc solutions for shaper optimization at the smallest dimensions are a perfect way to increase deposition rates for higher throughput and reduce material usage for critical processes using precious metals.

Got a BAK already?

Extend the life of your existing BAK with new process capabilities or the latest modern control systems.

Want to learn more?

Get the complete overview about the BAK Family.

Choose a Configuration

Standard Throw

Evatec has delivered in excess of 2000 BAK evaporators to the market, the majority of which are "standard throw", configured for conventional high precision coating processes on 2D and 2.5D substrates.

From the compact 0.5 meter BAK 501, optimized for university R&D to the giant BAV2000 handling 65 8 inch substrates in a single batch our systems can all be equipped with Evatec's own source and process control technologies to ensure high precision processes across in semiconductor, optoelectronics and photonics.

Choosing an Evatec evaporator means you can be confident

- you have access to the widest range of source technologies including thermal sources, effusion cells and e-guns

- you have access to Evatec's quartz and optical monitoring know-how

- our engineers are ready to support you with custom tooling options according to your application

- you can explore options for split chamber or assisted loading options if required

Lift Off / Extended Throw

Evatec 'lift off' systems have extended throw for process geometries where subsequent film patterning steps call for zero side wall coverage.

Extended throw system benefits

- Best control of 'lift off' processes

- Retention of full chamber flexibility for any future process requirements

Evatec 'lift off' systems use all the proven source and process control components of our standard throw platforms such as our EBS E gun technology and our Khan system and process controller but have lowered source chambers according to calotte geometry and substrate size to achieve the correct working distances required during evaporation. They are available in a wide range of platform sizes.

Just like standard throw systems however, "Lift Off" systems can also be specified in Split Chamber format or incorporate a handling system.

Looking for even more flexibility?

Ask about Evatec’s custom engineering solutions with interchangeable or motor driven tooling enabling both standard and "lift off" processes to be run easily in the same chamber as well as chamber extensions to run "in-situ" high uniformity etch prior to dep.

Split Chamber

Evatec "Split Chamber" systems integrate a valve between source and substrate chamber, allowing the sources to be kept 'ready' under vacuum during main chamber vent and substrate load/unload.

Split chamber benefits in a nutshell

- Ultra-stable source performance

- Shortened batch times for enhanced throughputs

- Ideal for doping processes, handling of reactive or sensitive coating materials

- "Pull out" configuration for source makes for rapid source maintenance / replenishment.

"Split Chamber" systems are already a well proven Evatec part of the BAK family. They use proven EBS E Gun technology and our Khan system and process controller. Taking the best from our 'Samson' platform, our new generation systems make life even easier with slide out source chambers for rapid refill and maintenance, a wider range of source technologies like extended capacity e guns or effusion cells, and the most accurate quartz and GSM optical monitoring control techniques ever with 'on line re-optimization' mid process for the most demanding thin film stack designs.

Sources & Tooling

Sources & Thickness Control

Your BAK is prepared for installation of a whole range of deposition and etch sources including accessories like front and backside heating systems.

The chamber base plate and side walls come with a series of standard feedthroughs enabling installation of the combinations of deposition and etch sources required for layer processing.

All our sources are engineered for 24/7 production, robust and easy to maintain, optimized for the lowest materials utilization and the best repeatability.

As process requirements change in the future, simply reconfigure your system by moving, exchanging or adding new ones, reconfigure your “Khan” control system in just a few minutes and you are ready to go. Control rates and terminate your layers with Evatec’s QCM quartz monitoring technology at 5 or 6MHz featuring high sampling rates, high speed switch between crystals and simultaneous control of up to 4 quartz heads from a single controller. For real time direct measurement of optical layer performance during deposition choose monochromatic or broadband optical monitoring techniques for UV, VIS and IR.

Tooling

Evatec’s portfolio of tooling solutions is designed to maximize batch capacity for evaporation processes without compromise on film quality. Choose from single piece and segmented domes with standard geometries or flip systems for double sided processes.

For high rate metallization our range of planetary system designs enables larger batch sizes and lowest materials utilization and for complex substrate geometries our engineering department offers a bespoke design service.

Where wall or door mounted large area rectangular sputter sources are specified, we offer proven rotary cage tooling designs for easy load / unload of carriers and maximum coating area per batch.

Watch the BAK 911 video

Watch the Multi-BAK video

Custom Solutions

Do you need a special chamber size, a special source or a tooling solution or a system suitable for R&D?

Custom build in a nutshell

- Access our design and mechanical engineering teams to design a custom chamber configuration

- Develop new sources and process control techniques through our applications specialists

- Configure a research tool for your University or Industrial Research Institute

The only limit is your imagination

- With a host of options for special geometries, source designs and process control techniques we hope you will find something within our standard portfolio to meet your needs, but with over 2000 systems delivered around the globe, we have access to a whole history of custom mechanical engineering solutions and special source designs. We can put together a custom BAK design that’s just right for you. The BAK UNI is just one example of an Evatec system focused specifically on the needs of Universities and Industrial Research Institutes.

Contact us to ask about our approach to custom build and find out more about BAK UNI capabilities and options.

Assisted Loading / Handling

BAKs can be delivered with a choice of assisted loading options that fit your throughput, handling and substrate tracking needs.

Single wafer / carrier transfer

Ideal for smaller size systems with limited substrate capacity, this front side transfer system means the process chamber can be kept under vacuum ready for coating once each position in the carrier is loaded. Access to the chamber for maintenance or source replenishment is via the grey room.

Assisted calotte load / unload ("Lazy Susan")

The preloaded calotte is transferred through the standard front door at atmosphere. Available across a wide range of system sizes, this system is ideal where loading heights make manual handling more difficult or loaded carriers are heavy to BAK in atmosphere. A second load / unload station can be integrated to reduce overall handling times.

Assisted load including load lock

Starting with all the flexibility of the BAK evaporator platform, the BAK911 helps you raise production to new levels of output. Convenient loading of the calotte before automated transfer to process chamber via lock ensures better vacuum conditions, shorter cycle times and the best levels of process repeatability. Why not watch the video then contact your local Evatec sales and service office to find out more.

Cassette-to-cassette with load lock – Multi BAK

For even greater level of automation why not configure up to 4 BAK 911 in a cluster configuration in the Multi BAK. With front end atmospheric robot serving all four process modules, this cassette to cassette solution for 6 and 8 inch eliminates all manual handling for high throughput typical applications across MEMS, power and wireless.

Retrofit

The “BAK” name may be 50 years old but with the choice of more deposition and control technologies than ever before, there’s never been a better time to bring your existing BAK up to the latest standards to achieve new levels of process control and yield in deposition of metals, oxides, TCOs and compounds.

Why Retrofit

- Enable new complex processes

- Improved process yields

- Increase uptime

- Track your processes – data logging & QA

- Replace obsolescent parts

Interactive Element

Handling

Automatic Loading System

- Calotte Loading System "Lazy Sue"

- Two Buffer Stations for loading and unloading calottes

- Hand controller for movement operations

Substrate Carrier

Evaporation

Standard and custom designs for complex substrate geometries and a large variety of coating materials

Feeding

Two position wire feeder for source replenishment in thick layer deposition.

Etch & IAD

Etch: Round and moveable linear sources for high rate, accurate in-situ deposition and etch processes.

IAD: Improved film qualities, lower process temperature, and shorter process times.

Glow: 700W or 2000W according to application.

Film thickness measurement

Optical measurement

RGA & BPG

BPG: Additional pressure gauge for the use of process gases.

Residual Gas analyzer is used to analyze atomic and molecular masses inside the vacuum chamber.

Temperature controlling

Vacuum creation

Integrated cryo- and forepumps ensure stable high-vacuum conditions and rapid recovery times.

Additional Meissner water trap can be added to vacuum pumping systems to remove unwanted water.

Buying a new Evatec tool is just the first step in a long term partnership. From initial ramp up support to ongoing maintenance or retrofits adding new capabilities, maximise both uptime and tool working life together with Evatec’s local customer service teams.

- We can help you plan and manage your stocks

- Use our exchange programmes to minimize downtimes

- Our local Field Service Engineers on hand when you need us

- Maximizing output - From Continuous Improvement Programmes (CIP) to new process installations

- Add new capabilities to support your technology roadmaps

- Helping you extend tool working life

- Helping you to help yourself

- Tailored just for you - At Evatec or in your own fab

Read more about the BAK Family in our LAYERS magazine

Multi BAK – Pushing Boundaries in Evaporation Technology

Europe – A powerhouse in III-V solar cells manufacturing